A built-in ice maker can stop working for many reasons. Power, water, or temperature issues are the most common. Take a look at this table showing what often goes wrong:

| Failure Cause | Diagnostic Indicator |

|---|---|

| Power Problems | LED codes flash to show sensor faults |

| Water Supply | No water fill or slow trickle means less or no ice |

| Temperature Issues | Delayed harvest cycles or long ice formation times signal trouble |

Key Takeaways

- Check power first by ensuring the ice maker is plugged in, switched on, and the breaker is not tripped. Reset the unit if needed and watch for flashing LED codes that signal problems.

- Inspect the water supply by looking for kinks or blockages in the water line, making sure the valve is open, and replacing the water filter regularly to keep water flowing and ice tasting fresh.

- Keep the freezer temperature at or below 0°F (-18°C) to allow proper ice formation. Avoid overloading the freezer and keep the door closed to maintain cold air and prevent ice maker jams.

Built-in Ice Maker Troubleshooting Checklist

Power Supply Issues

Power problems often stop a built-in ice maker from working. Many users find that their ice maker does not turn on because it is not plugged in or the switch is off. Sometimes, a tripped breaker or a blown fuse cuts off power. Real-world repair guides show that checking the power source is one of the first steps. People often forget to reset the ice maker or check if the unit is switched on. If the ice maker has a display or LED lights, flashing codes can point to sensor faults or power issues.

Tip: Always check the outlet and power cord before moving on to other steps.

- Make sure the ice maker is plugged in.

- Check if the power switch is on.

- Look for any tripped breakers or blown fuses.

- Reset the ice maker if it has a reset button.

Water Supply Problems

A built-in ice maker needs a steady water supply to make ice. If the water line is kinked, blocked, or disconnected, the ice maker cannot fill the tray. Sometimes, the water valve is closed or there is low water pressure. If the ice maker is not getting enough water, it may make small cubes or no ice at all.

Note: Listen for the sound of water filling the tray. If you do not hear it, check the water line and valve.

- Inspect the water line for kinks or leaks.

- Make sure the water valve is open.

- Test the water pressure if possible.

Temperature Settings

The freezer must stay cold enough for the built-in ice maker to work. If the temperature is too high, ice forms slowly or not at all. Most ice makers need the freezer set at or below 0°F (-18°C). If the temperature rises, the ice maker may delay its cycle or stop making ice.

Tip: Use a thermometer to check the freezer temperature. Adjust the settings if needed.

- Set the freezer to the recommended temperature.

- Avoid overloading the freezer, which can block air flow.

- Keep the door closed as much as possible.

Control Arm or Switch Position

Many built-in ice makers have a control arm or switch that starts or stops ice production. If the arm is up or the switch is off, the ice maker will not make ice. Sometimes, ice cubes block the arm and keep it in the off position.

Tip: Gently move the control arm down or flip the switch to the on position.

- Check the control arm or switch.

- Remove any ice blocking the arm.

- Make sure the arm moves freely.

Clogged Water Filter

A clogged water filter can cause big problems for a built-in ice maker. When the filter gets dirty, water cannot flow well. This leads to smaller, fewer, or even no ice cubes. Sometimes, ice tastes odd or smells bad because impurities pass through a worn-out filter. Product tests show that removing the filter and using a bypass plug can restore water flow, proving the filter was the problem. Experts recommend changing the filter every six months, or more often if the water is hard or has lots of sediment.

- Replace the water filter if it is old or dirty.

- Use a bypass plug to test if the filter is the issue.

- Mark your calendar for regular filter changes.

Frozen or Jammed Components

Ice can build up and jam moving parts inside the ice maker. Sometimes, the ice tray or ejector arm freezes in place. This stops new ice from forming or being released. If the ice maker sounds like it is working but no ice comes out, check for frozen or stuck parts.

Tip: Unplug the ice maker and let it defrost if you see ice buildup.

- Look for ice jams in the tray or chute.

- Gently clear away any blockages.

- Defrost the ice maker if needed.

A built-in ice maker works best when all these parts function smoothly. Regular checks and simple fixes can keep the ice flowing.

How to Fix Common Built-in Ice Maker Problems

Restore Power to the Ice Maker

Power issues often stop an ice maker from working. First, check if the unit is plugged in and the outlet works. Sometimes, a tripped breaker or blown fuse cuts off power. If the ice maker has a reset button, press it to restart the system. Many models show LED codes when there is a sensor or power problem. These codes help users spot the issue quickly. If the lights do not turn on, the ice maker may need a new power cord or switch.

Tip: Always unplug the ice maker before checking wires or connections for safety.

Check and Clear the Water Line

A steady water supply keeps the ice maker running smoothly. If the water line gets kinked or blocked, ice production slows down or stops. Users should inspect the water line for bends, leaks, or clogs. Make sure the water valve is open. If water pressure feels weak, test it with a gauge. Low pressure can mean a problem with the main supply or the inlet valve. Cleaning or replacing the water line often restores normal flow.

Set the Correct Freezer Temperature

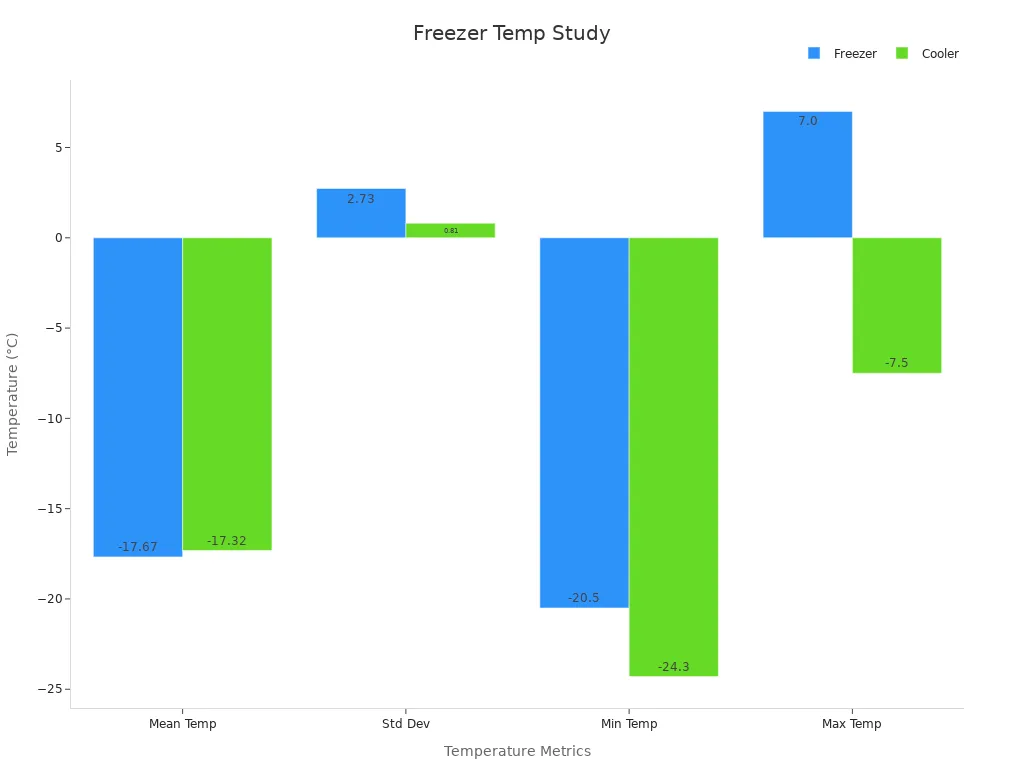

The freezer must stay cold enough for ice to form. Most ice makers work best at 0°F (-18°C). If the temperature rises, ice forms slowly or not at all. A recent 68-day study tracked freezer temperatures and found that even small changes can affect ice production. The table below shows how freezer temperatures compare to coolers:

| Metric | Freezer | Cooler Average | Difference (Freezer – Cooler) |

|---|---|---|---|

| Mean Temperature (°C) | -17.67 | -17.32 | -0.34 (95% CI: -0.41 to -0.28) |

| Standard Deviation | 2.73 | 0.81 | 2.58 |

| Minimum Temperature (°C) | -20.5 | -24.3 | -8.2 |

| Maximum Temperature (°C) | 7.0 | -7.5 | 23.1 |

When the freezer temperature rose above 0°C, ice production dropped. Keeping the freezer at the right setting helps the built-in ice maker work at its best.

Adjust the Control Arm or Switch

The control arm tells the ice maker when to start or stop making ice. If the arm sits in the wrong position, ice production stops. Sometimes, ice cubes block the arm and keep it from moving. Users have fixed ice makers by gently moving the arm down and resetting the device. Technical guides say that about 15% of ice maker problems come from control board or arm issues. If the control arm feels loose or broken, a professional may need to check it.

- The control arm signals the ice maker to start or stop.

- A jammed or blocked arm can stop ice production.

- Resetting the device after moving the arm often solves the problem.

- Control board issues may need expert help.

Replace or Clean the Water Filter

A clean water filter keeps ice clear and fresh. Over time, filters clog with dirt and minerals. This makes it hard for water to flow and can let bacteria grow. Some filters use silver to slow bacteria, but it does not stop all germs. Experts recommend cleaning or changing the filter often. If the filter looks dirty or ice tastes odd, replace it right away. Many users keep a spare filter on hand for quick swaps.

- Filters clog with use, blocking water flow.

- Dirty filters can let bacteria or dirt into the ice.

- Cleaning or replacing the filter improves ice quality and flow.

- Standard filters remove most bacteria and protozoa, but not all viruses.

Defrost or Unjam Ice Maker Parts

Ice can build up inside the ice maker and jam moving parts. If the tray or ejector arm freezes, new ice cannot form or drop. Unplug the unit and let it defrost if you see ice buildup. Use a plastic tool to gently clear away any stuck ice. Never use sharp objects, as they can damage the machine. If the auger motor or water inlet tube freezes, a professional may need to help.

Note: Regular defrosting keeps the built-in ice maker running smoothly and prevents jams.

When to Call a Professional

Some problems need expert help. If water pressure drops below 20 psi, the inlet valve may need replacing. If the freezer stays above 0°F (-18°C) and ice production does not improve, a technician should check the system. Broken control arms, frozen motors, or blocked water lines often require special tools and skills. When simple fixes do not work, call a professional to avoid further damage.

| Criteria / Issue | Measurable Threshold or Condition | Recommended Action / When to Call a Professional |

|---|---|---|

| Water pressure feeding valve | Less than 20 psi | Replace water inlet valve |

| Freezer temperature | Should be 0°F (-18°C) | Call professional if ice issues persist |

| Control arm position | Must be “on” and not broken | Tighten or replace if needed |

| Frozen water inlet tube | Ice blockage present | Professional defrost recommended |

| Frozen auger motor | Motor frozen, no dispensing | Professional repair needed |

| Persistent unresolved issues | Troubleshooting unsuccessful | Schedule professional repair |

Many users try simple fixes first. If the built-in ice maker still does not work, a professional can find and fix hidden problems. Regular maintenance and quick repairs keep the ice flowing for everyone.

Most built-in ice maker problems come from power, water, or temperature issues. Regular maintenance makes a big difference:

- Repair experts say routine upkeep helps refrigerators last over 12 years.

- Consumer Reports found that cleaning coils and changing filters keeps built-in ice makers running smoothly.

If problems continue, call a professional.

FAQ

Why does my built-in ice maker make smaller ice cubes?

Small cubes often mean low water flow. He should check the water line and replace the filter if needed. Clean water lines help restore normal cube size.

How often should someone clean the built-in ice maker?

Most experts suggest cleaning every three to six months. Regular cleaning keeps ice fresh and prevents buildup. He can follow the manufacturer’s instructions for best results.

What should someone do if the ice tastes or smells bad?

He should replace the water filter and clean the ice bin. Sometimes, running a cleaning cycle helps. Fresh water and a clean bin improve taste and smell.

Post time: Jun-16-2025